Mechanizing dairy farms

”Since I bought the equipment from BrazAgro Ltd., I have managed to process my feed at the farm level. This is both silage and mash feed. Silage-making become faster compared to when I used to hire a forage shredder. The multipurpose equipment has enabled us have a mini animal feed plant at the farm where we can make our own animal feed. This has made feed production economical and reliable.”

Peter Kimani, Dairy Farmer in KiambuBACKGROUND

Dairy farmers in sub-Saharan Africa suffer from the high cost of feed. Small plots also lead to low yields of dairy production.BrazAgro’s solution entails the integrated processing, shredding, milling and mixing of feed for dairy cattle on small-scale farms. The mechanization programme embraces carrying and cutting forages, milking cows and delivering production to the milk collection service point

WHAT’S INVOLVED

Practical solutions

- BrazAgro imports and distributes quality, simple machinery to streamline the production of fodder for dairy farming

- The company also trains Kenyan dairy farmers on silage-making to ensure the continuous availability of feed

EXPLORE THIS SOLUTION

- Results show that the use of farm machinery for processing forages significantly increases potential herd size. Moreover, the larger herd size is related to a farmer’s ability to operate machines to handle various farm activities. Mechanization has enabled farmers to keep more dairy cows with comparatively small increases in farm labour.

- Mechanization can greatly reduce the time and cost of preparing feed.

- The quality of feed is also improved. This consequently leads to higher yields and better food security

Countries involved

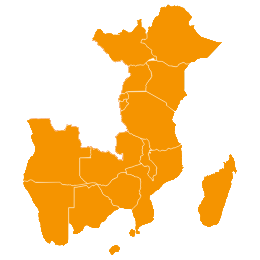

Kenya, Uganda Tanzania, Rwanda

Project partners

UN Food and Agricultural Organisation (FAO), the US Agency for International Development (US AID) and Ministry of Agriculture (Kenya)

Project dates

2011 - 2021

Share this solution

Bookmark this solution

BookmarkShow Full Solution

Summary

BrazAgro Limited is a leading supplier of farm machinery from Brazil to small-scale farmers in East Africa. The company has trained Kenyan dairy farmers to produce feed so that it is continuously available. This has enabled dairy farmers to process quality feed within a short period of time while reducing the feeding time of animals, thereby contributing to significantly increased milk production.

The Challenge/Problem

Throughout East Africa, the rapidly growing human population has led to ever diminishing plots of land available for livestock farmers to raise animals. Further, overgrazing on the small plots available has caused serious soil erosion. Dairy farming in particular is adversely affected, with farmers forced to transition from free-range grazing to using animal paddocks to intensively feeding cattle within the confined spaces available.

For cows to provide abundant milk in these circumstances, a higher quality of feed is needed than is generally available. Most dairy cattle in East Africa produce milk far below their potential due to poor feed quality and quantity.

Solution

The solution is based on providing high-quality fodder that is locally available. In East Africa, this comprises a selection of maize stalks, napier grass, sorghum stalks, yams and potato vines, all of which need to be well shredded for effective ingestion. To this shredded material, bran, dairy meal and feed concentrates are added to optimize nutritional value.

For the fodder to be effectively shredded and mixed, mechanization is essential, and this is BrazAgro’s core business. The company provides integrated processing, shredding, milling and mixing equipment for feed production at a scale accessible to smallholder farmers. It also provides solutions for ancillary dairy activities, including carrying and cutting forages and milking equipment. This equipment is complemented with training on its safe and effective use.

Within Kenya, the company targets smallholder farmers in Kiambu County, Central, Rift Valley and the western and eastern areas of Kenya – areas that have the greatest potential for dairy farming, given the number of commercially oriented smallholder farmers and high populations that create strong local demand for dairy products. The company has also engaged with smallholder dairy farmers in Uganda, Tanzania, Rwanda and Burundi, but not on the same scale as in Kenya.

Traditionally, these were not considered livestock areas because of the small landholdings there, but farmers have transitioned to intensive herding that can be carried out on even less than an acre.

The company uses diverse marketing techniques, including field days, agricultural shows and digital and radio advertising. COVID-19 is forcing a further migration to digital marketing, because farmers are apprehensive of face-to-face meetings.

Sales in feed-shredding machinery have grown from $39,000 per year upon the initiative’s inception to $260,000 per year today, a strong indication of dairy farmers’ commitment to improving their operations. This division of the company is commercially sustainable.

Results

The results show that using farm machinery to process forages significantly increases the size of herd a famer can successfully keep and feed. Mechanization typically leads to an increase in the number of dairy cows farmers tend, because the farmers’ dairy operations become more commercially viable and require less farm labour.

Anecdotal evidence derived from the large number of customers, combined with the numerous enquiries from farmers at agricultural shows, indicate that this solution is desired and sustainable.

Lessons Learned/Potential for replication

- The last ten years have shown that mechanization can greatly improve dairy production while reducing the cost of preparing feed. Mechanization improves feed quality, leading to higher milk yields and improved community nutrition, rural incomes and national food security.

- The most serious constraint on future growth is farmers’ access to credit to buy the machinery: the unit cost of machines is beyond the reach of most farmers unless they borrow. Farmers tend to be high-risk borrowers, frequently lacking car logbooks, which are very commonly used as security for loans from banks and microfinance organisations. Asset finance is also problematic because farm machinery loses almost all its value within two years.

- The need to import forage equipment is another constraint on efficient operation, but local manufacturing – even if it were of sufficient quality – lacks the economies of scale compared to imports from Brazil. Kenya’s dairy industry would have to grow substantially for this situation to change.

Next Steps

- A credit program for procuring and maintaining machinery is required to help the farmers mechanize their operations.

- More farmers need to be trained on the importance of sustainable methods of feed production to ensure that mechanization is fully integrated within the local community. Monitoring and evaluation of farmers’ progress is to be implemented to ensure that farmers are guided through the whole process

- Most significantly, BrazAgro needs to acquire the financial tools necessary to have adequate inventories of equipment. Discussions are underway with various institutions, but COVID-19 has hindered progress.

Last update: 07/07/2021